Miyahara Technology

World-Class Machining

Technology

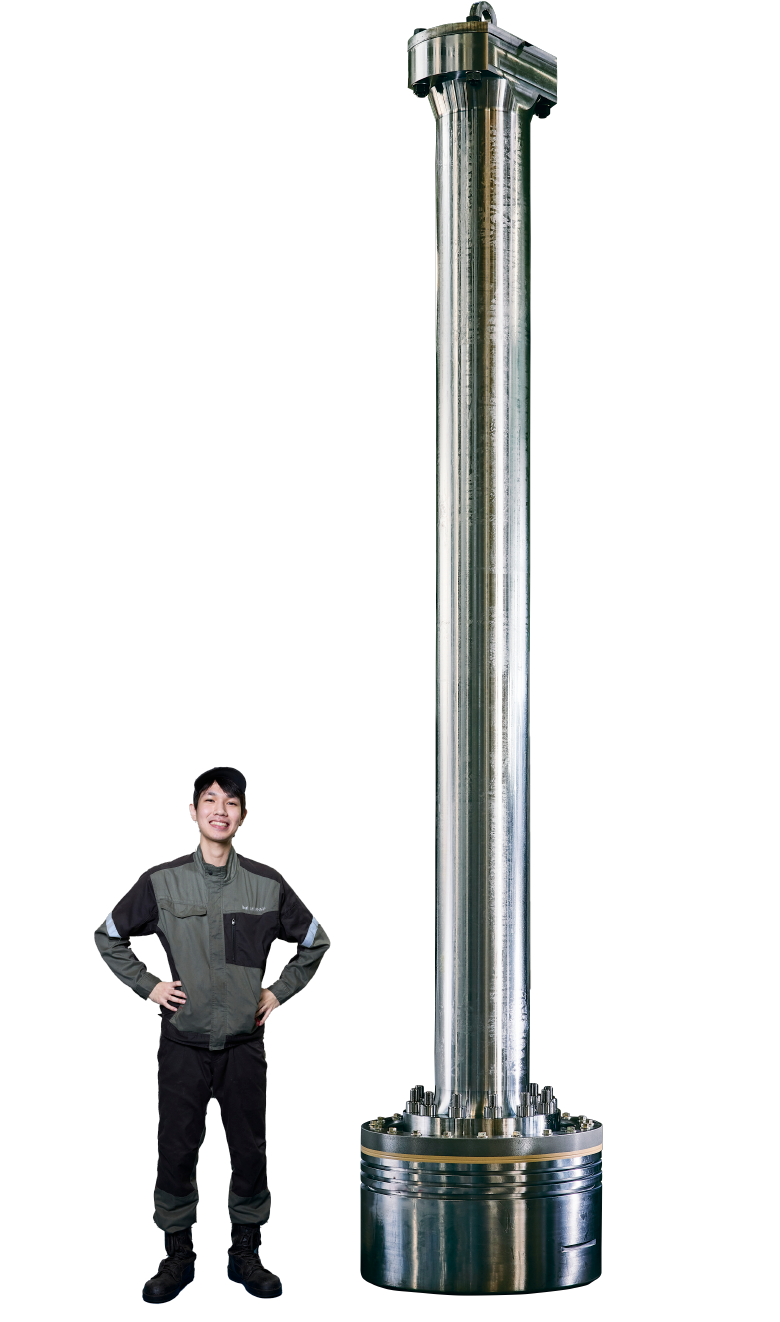

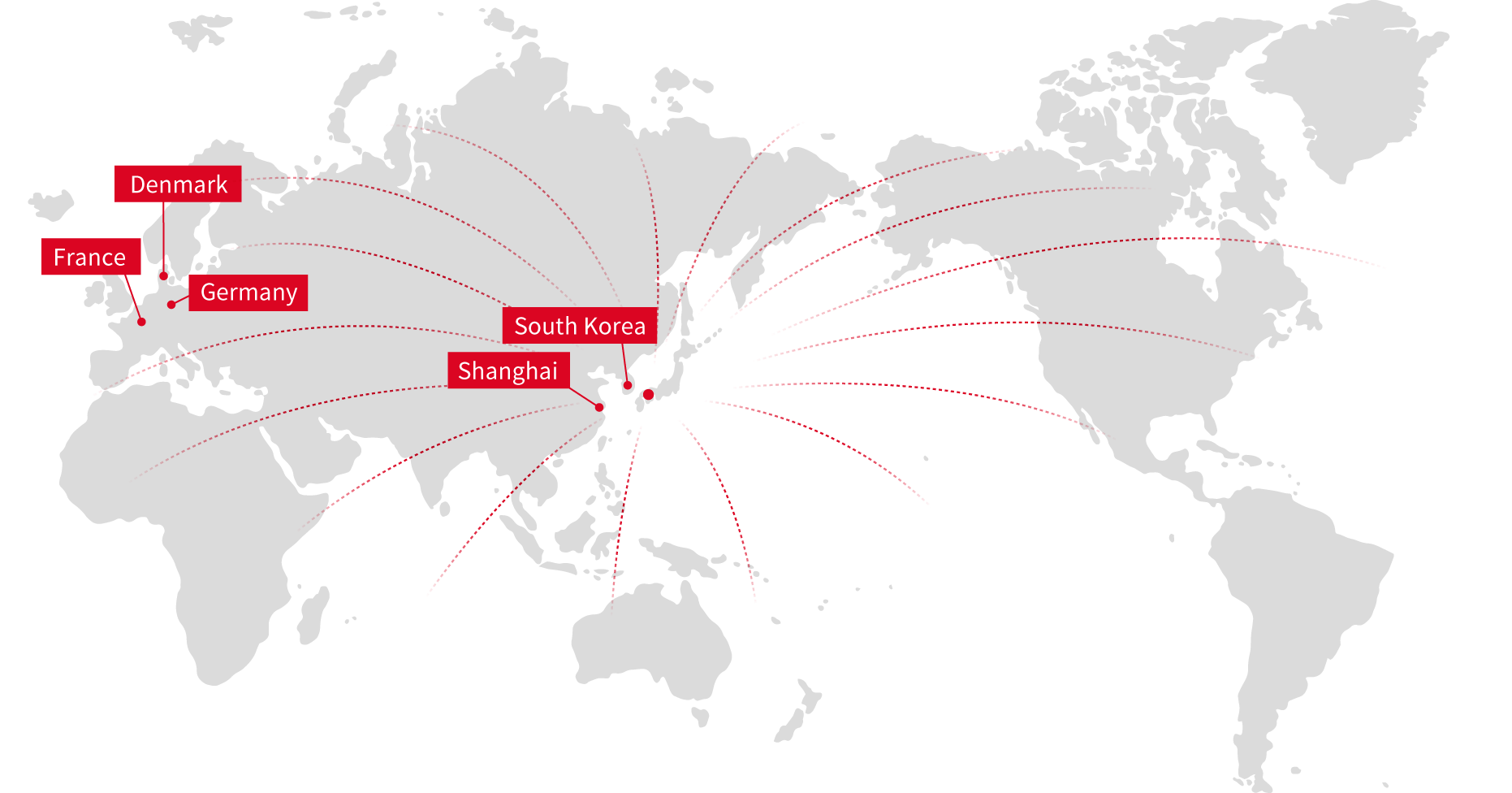

Miyahara Manufacturing proudly produces key components for large marine engines in partnership with Mitsui E&S, which holds the largest domestic market share in the production of large marine engines. Mitsui E&S has a licensing agreement with MAN Energy Solutions, a global leader in the field, and our company, which manufactures the engine components, also has a sublicense agreement.

Integrated Production

System

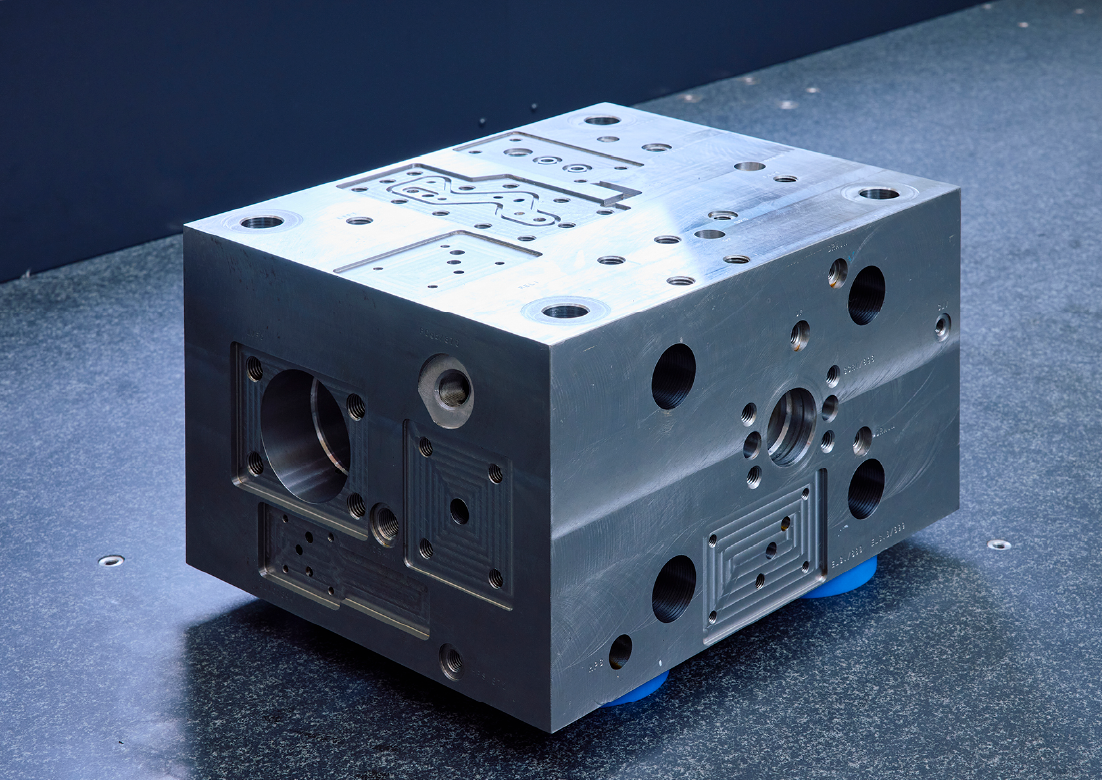

One of our strengths is our ability to handle everything in-house, from machining to assembly. This enables us to reduce costs and respond flexibly to customer needs. Additionally, we have expertise in combining in-house machined components with externally sourced parts to create finished units. With various options available in our manufacturing processes, we can achieve efficient production.

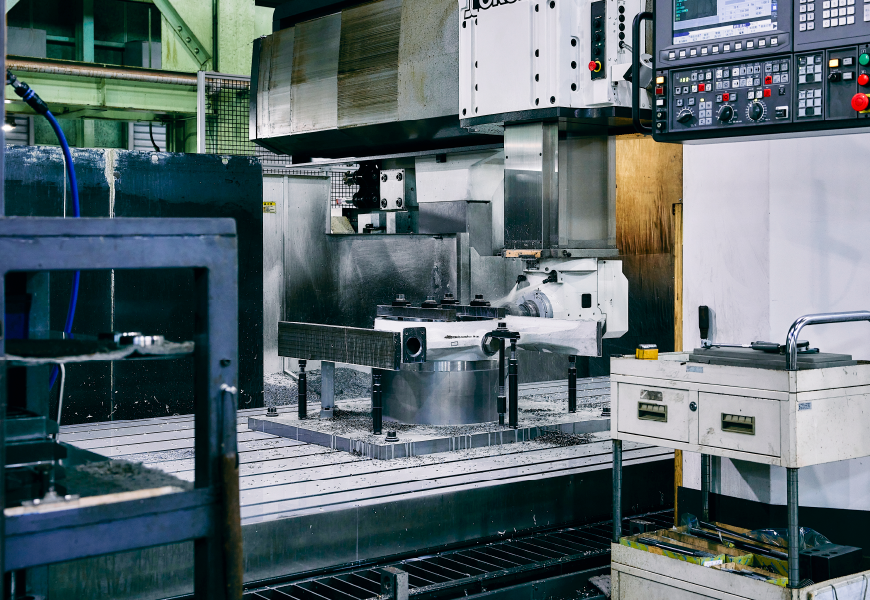

Wide Range of Machining Capabilities

Our strength lies in our ability to handle a wide range of machining processes, including cutting, grinding, drilling, thread rolling, coating, and heat treatment. We can process parts of various sizes, from palm-sized components to large parts several meters in length. With approximately 50 machining machines, including CNC lathes, various types of machining centers, high-frequency hardening machines, and high-speed flame spraying machines, we continue to upgrade to the latest equipment.